The Microfilm Shop is the largest independent supplier of microfilm jackets in Europe and can offer very competitive prices. If you have any unusual requirements, please contact us.

The Microfilm Shop manufactured jackets have been subjected to and passed the rigorous Photographic Activity Test (PAT) test – ANSI IT9.16 *. The Photographic Activity Tests are used to ensure no adverse reaction takes place between the component parts of the microfilm jacket and the silver halide film enclosed therein.

* Data from independent tests performed at the Image Permanence Institute at Rochester Institute of Technology.

What is a Jacket?

A Microfilm jacket is made up of 2 pieces of polyester film bonded together to hold strips of film. Jackets are made in various sizes and hold 16mm or 35mm microfilm or a combination of both.

The main advantage of a jacket is that it is a unitised record. A jacket is similar to a paper file in that it can still be held in the hand and it is still recognisable as the original hard copy file. Like a file it can be added to or edited at any time. A microfilm jacket system is ideal for updateable document management files such as personnel, insurance, student or customer files etc.

Also, like any filing system the jackets can be indexed by colour, notch or bar code etc. to enhance retrieval and security.

A jacket system has all the advantages of a conventional paper file plus all the benefits that microfilm can add.

Laminate

Microfilm jackets are manufactured using a lamination system. Lamination is basically a gluing process that bonds the two halves of the jacket together using lengths of special polyester hot melt glue. The hot melt is either used in its clear state to produce clear laminate jackets or dyed blue to produce blue laminate jackets. Choice of colour of laminate is down to personal preference, it does not effect the performance of the jacket.

Jacket Formats Available

Both the blue and clear laminate jackets are held in the metric size (105 x 148mm – A6) and imperial size (103 x 152mm – 6″ x 4″) in all formats. Shown below is our main range of jackets, however, we also supply 5 x 3″, aperture card size, 8 x 5″, 86 x 127mm, 76 x 127mm, 86 x 187mm, 128 x 101mm and 152 x 103mm jacket formats.

Jackets can be made to just about any size or format to suit your specific need.

Please talk to us if you have an unusual requirement.

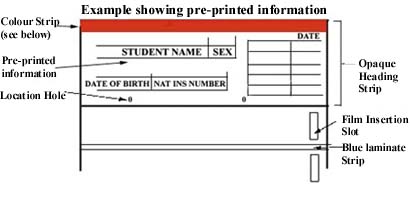

Printed Heading Strips

All the above jacket formats come with a translucent heading strip onto which the user can type/print indexing information relating to the microfilm contents of the jacket. The Microfilm Shop can pre-print jacket heading strips on request.

The heading strip is translucent so that when duplicate copies of the jacket are made, the information on the heading strip will appear on the duplicate copy.

Colour Striping

A 2mm wide colour stripe can be added to the top of the heading strip to distinguish different subjects or groups etc. at a glance.

Stock Colours Available

Note:

The colours shown above are meant as a guide only and are not considered to be a detailed representation of the exact colours available.

Notch Coding

Notch codes are used to further sub-index within jacket systems. It involves cutting notches at different points along the top of the jacket. Groups of jackets would have the notch in the same position enabling the user to easily identify a misfiled jacket belonging to a different group. The Microfilm Shop can notch jackets for you or supply a jacket notching machine.

Jacket/Fiche Protection and Duplicating Sleeves

These sleeves are made so that A6 microfilm jackets or microfiche can fit into them. Heavy duty protection sleeves act purely to protect the jackets from excessive handling. Duplicating sleeves comprise one thick piece of plastic and one thin to allow for the duplicating of jackets whilst in the protection sleeve.

Continuous Stationery

All of our microfilm jackets can be supplied pre-mounted onto computer stationery in such a way that the index can be typed/printed straight on to the jackets using your computer or word processor. All types of computer stationery can be supplied.

Sequential Numbering

When converting a purely sequential, numeric reference system (such as the storage of invoices) onto jackets, it is possible to have the numbers pre-printed onto the jackets at the time of ordering. There is no limit to the amount of digits that can be printed onto the top of the jacket. Set analogue prefixes or suffixes can also be printed at the same time.

Jacket Labels

A further efficient way to index jackets is by the use of specialised title labels. The type used for microfilm jackets has two half moon cut outs on the bottom of the label so that the location holes are not covered over. This type is available either translucent (JLT) for occasions when fiche duplicates are going to be prepared, or made of opaque (JLO) paper for when duplicates are not required or the previous heading needs to be covered. Both types are supplied on computer stationery.

Jacket Loader

There is a complete range of equipment available to mount microfilm into all formats of microfilm jackets. These include simple hand tweezers, basic machines that are totally manual, semi-automatic models and completely automated models. All are available from The Microfilm Shop. Click here to take a look at the ABR400.

Canon Jackets

The Microfilm Shop can supply a full range of Canon type jackets. These are very similar to normal jackets but are specifically designed to be loaded using a Canon jacket loader. The main difference being that the film insertion slot is ‘moon’ shaped rather than rectangular, as is normal.

CAR (Computer Aided Retrieval) Jackets

jac carThese jackets are designed specifically for jacket systems that use Computer Aided Retrieval for all their documents. Each frame of microfilm is given a unique reference number using a grid pattern (i.e. A3 or D12) to locate its exact position in the jacket. This is achieved by pre-printing a grid pattern on the glue lengths of the jacket. The computer contains the jacket identification number, batch, date or subject as well as key document description and location. Upon request, the terminal operator receives the jacket identification and document x and y location from the computer database.